::Hygroscopic Climatic Modulated Boundary::

The hygroscopic building envelope is an adaptive biomimetic skin where all of the components for dehumidifying air and harvesting energy and water are placed within the building façade.

The demands on conventional HVAC systems to cool and dehumidify interior spaces for comfort in hot and humid climates requires more energy use in building operations. Energy use in buildings and production of green house gases contributes to global climate change.

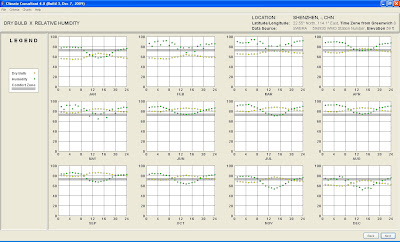

Hot and humid climates are generally hot in the summer, cool in the winter, and has significant year round precipitation. The climate type is prevalent in Gulf Coast, Mid-Atlantic, Mississippi Valley, and Southern Appalachia in the United States. Global distributions of this climate are present in rapidly developing areas of rising fossil fuel use and water needs in China, Australia, and South America.

The hygroscopic building envelope uses a solution to interact with exterior hot, humid air to absorb water and dehumidify outside air for use in interior spaces to satisfy comfort requirements.

It is a filter that allows air from the outside to pass through and enter a cavity where a hygroscopic solution collects water and photovoltaic fibers collect solar energy allowing dehumidified air to pass through vent flaps to the interior.

A hygroscopic building envelope that harvests water from humid air must use a hygroscopic brine solution. The hygroscopic solution readily absorbs moisture in the air through the attraction of strong ionic bonds of negative ions of the brine to positive ions of hydrogen in water vapor.

Water harvesting uses a capillary transport sensing tube system, generative air circulation and integrated solar cells in an experimental fiber form. Controls within the material system respond to varying environmental conditions for the production of water, energy and air movement.

It differs from conventional systems because it does not depend primarily on the supplying or removing of energy through mechanically dominant active means based on fossil fuels.

It uses micro wind driven generators and thin and flexible solar collecting photovoltaic fibers for onsite energy generation that supports the hygroscopic process.

The hygroscopic building envelope can sense and respond. Driven by the varied, differential, gradient and dynamic conditions of the exterior environment of hot and humid climate, the hygroscopic building envelope responds to these conditions by altering the absorption characteristics of the hygroscopic brine solution.

A color change property in the hygroscopic brine solution is visible to both the building occupant and the observer from the exterior of the hygroscopic boundary. The experience of the hygroscopic boundary working fluid in operation is dynamic and real-time response to the environment.

The hygroscopic building envelope employs the use of sodium chloride and emerging natural high strength organic bio-plastics for the transport system.

The hygroscopic building envelope system reduces the need for conventional air conditioning systems to dehumidify interior air. The HVAC system is only needed to cool the interior air. This reduces one of the major energy usages in building operations typically required to cool and dehumidify interior spaces in hot and humid climates.

Hygroscopic building envelope proposed benefits::

Improved Indoor Air Quality:

Hygroscopic building envelope uses natural ventilation as well as a computational control system for increasing ventilation through renewable sources to potentially improve indoor air quality. The hygroscopic brine solution uses a salt that naturally inhibits microbiological growth by maintaining lower humidity levels. Lower humidity in building interior spaces prevents moisture, mildew and rot in building materials.

CFC Free:

Hygroscopic brine solution does not use CFC’s for moisture removal.

No Duct Systems:

Hygroscopic building envelope has the potential to eliminate ducts as dry air is delivered to the interior space for active sensible cooling system.

Lower Peak Electric Demand:

Switch latent cooling to alternate energy sources such as thermodynamic transformation in entropy energy recovery, fiber solar photovoltaic system, air flow pressure and driven wind generators, steam, and heat recovery.

Increased Comfort via Envelope Dominant System:

Independent control of humidity and temperature because hygroscopic building envelope controls humidity while conventional system or active chilled beam systems controls temperature.